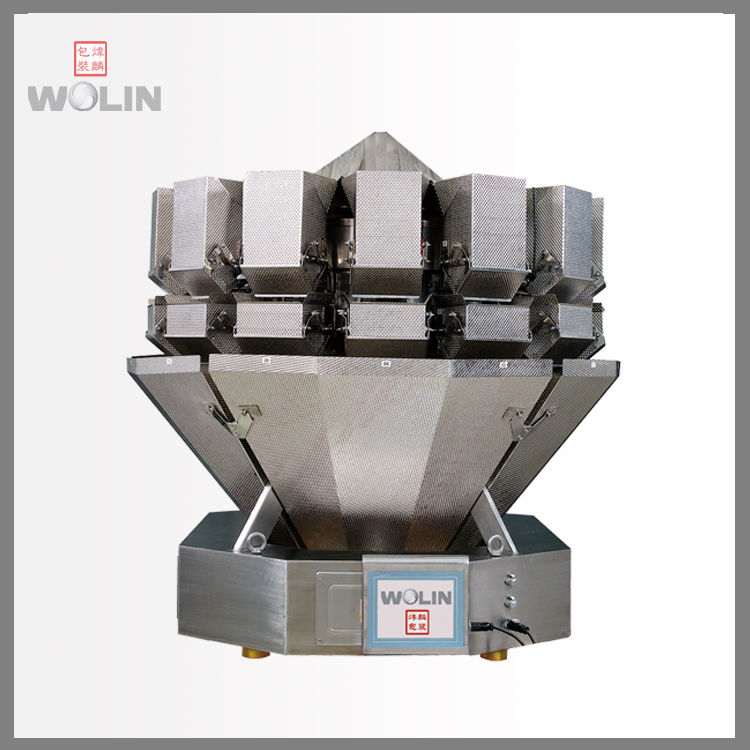

Weighlin's new modular multi-head combination weighing filler series is with the feature of hi-speed, hi-accuracy and reliable performance. Adopting numbers combination theory, CPU auto calculate and choose the closest target weight combination hoppers to dump to the downstream units, such as manual filling, various packing machine, tray/bottle/bucket/can filling device, also integrated with weight checker, metal detector or X-ray. Widely apply in food or non-food packing industry.

sales@weighlin.com

sales@weighlin.com