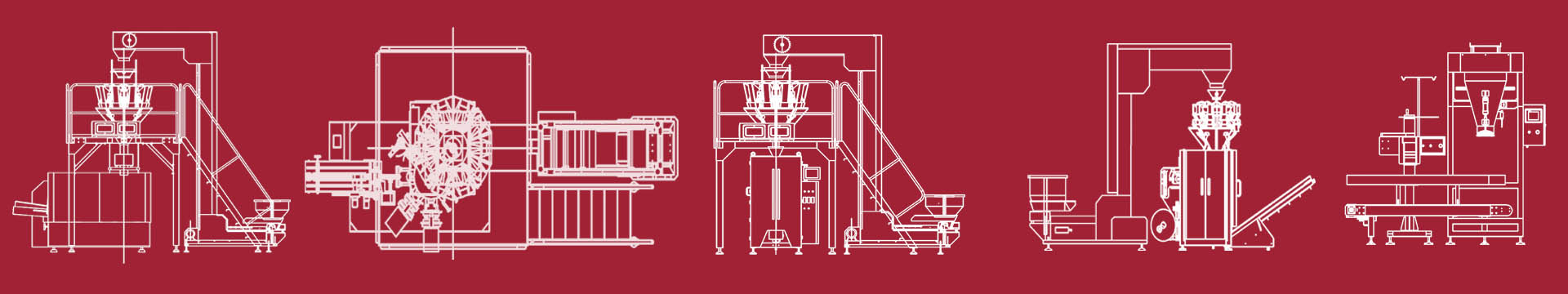

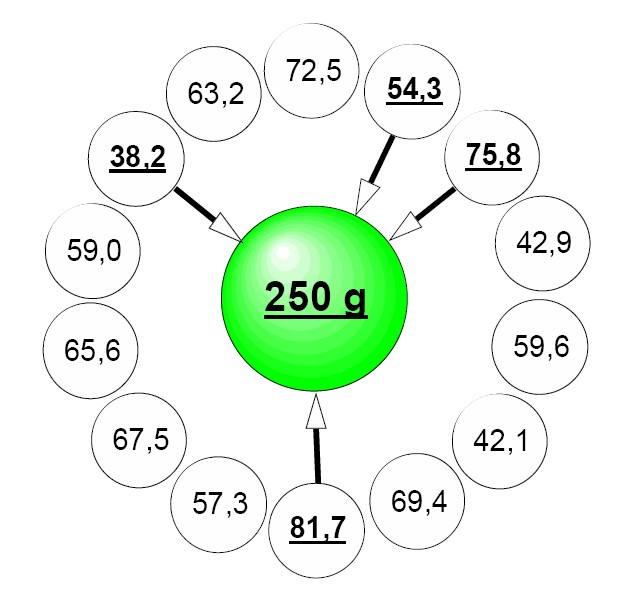

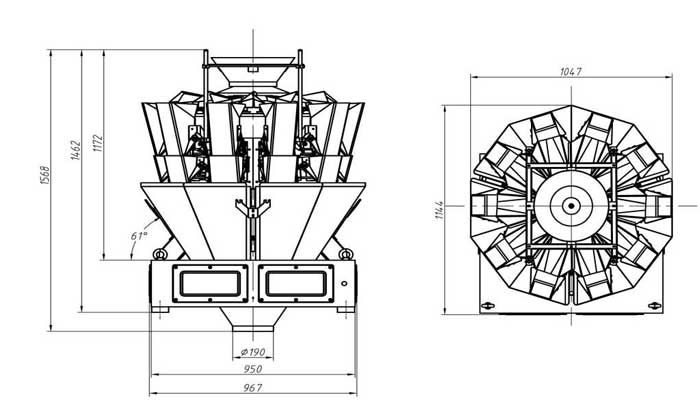

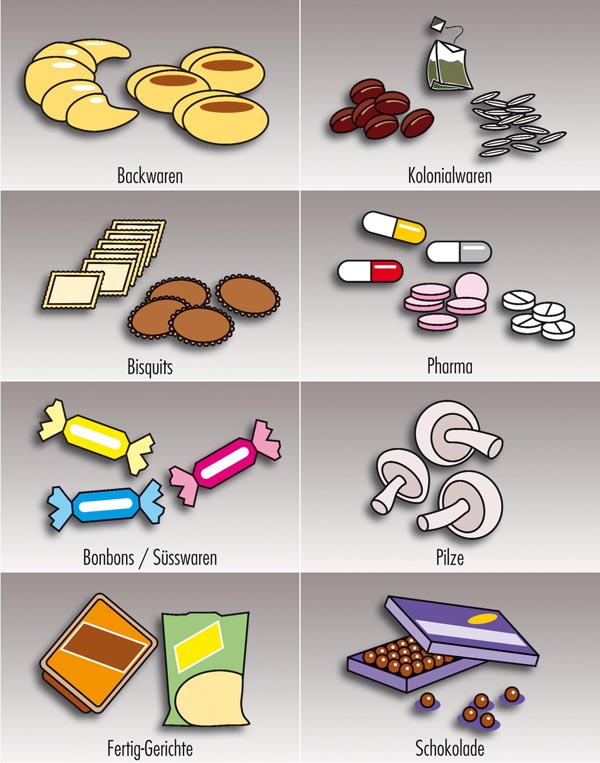

Weighlin's new modular multi-head combination weighing filler series is with the feature of hi-speed, hi-accuracy and reliable performance. Adopting numbers combination theory, CPU auto calculate and choose the closest target weight combination hoppers to dump to the downstream units, such as manual filling, various packing machine, tray/bottle/bucket/can filling device, also integrated with weight checker, metal detector or X-ray. Widely apply in food or non-food packing industry, such as rice, seeds, nuts, candy, snack food, potatos chips, IQF food, biscuits, bread, fresh vegetable and fruits, hardware or plastic parts, etc. Besides, as for fragile, hard-flowing, long-stick or mixed products, based on years successful experience, we can custom mechanical and program to meet the project requirements, such as dimple plate, timing hopper, inclined feeder pan, piece counting, 1 to 2-3-4-5 points dump or IP65 waterproof design, etc.

sales@weighlin.com

sales@weighlin.com