PE material is also workable.

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

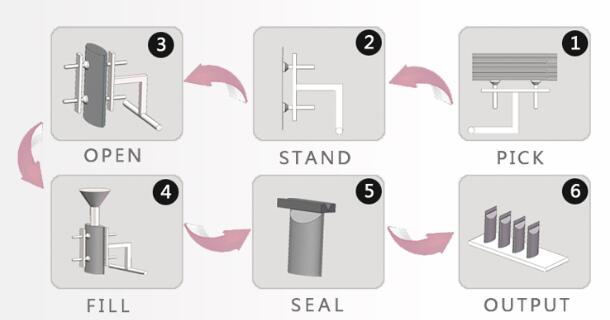

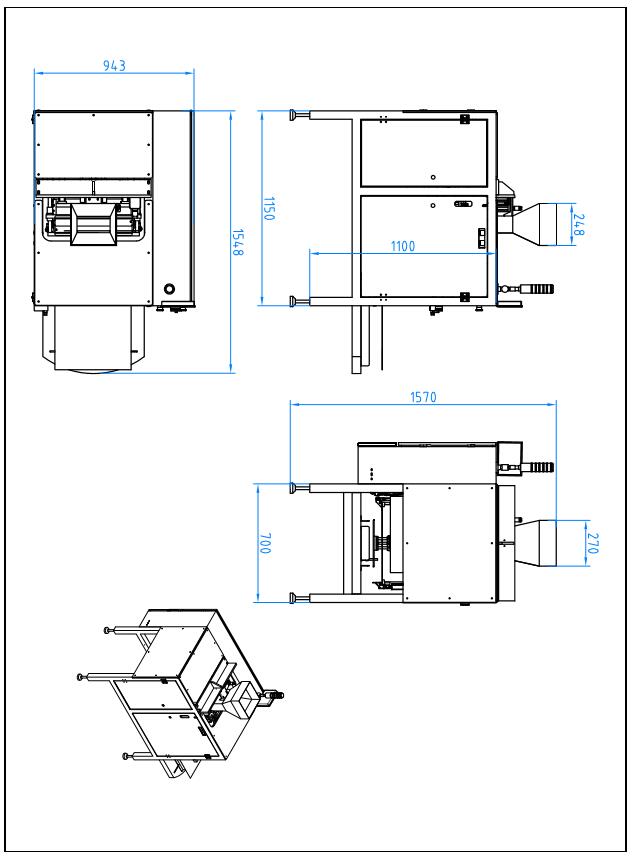

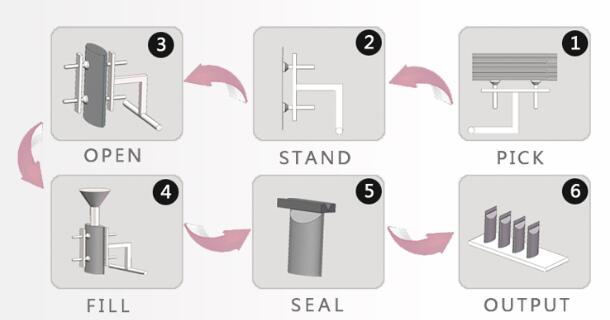

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market