-

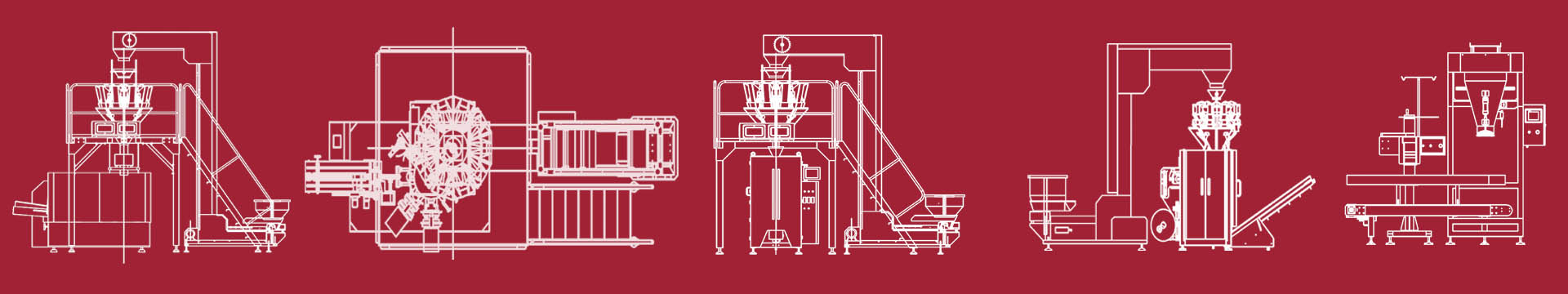

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

-

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

-

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

-

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

-

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

-

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

Single Lane Round Corner Bag Packing Machine

Automatically feeding,measuring volume, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches, finished product conveying Applicable for the powder product, such as coffee powder, seasoning powder, sugar or juice powder, etc

MESSAGE US

Automatically feeding,measuring volume, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches, finished product conveying. Applicable for the powder product, such as coffee powder, seasoning powder, sugar or juice powder, etc.

(1). Famous brand PLC control system,large touch screen,convenient to operate;

(2). Film drawing down system by reliable servo motor control.

(3). Each lane dosing by servo motor driving;

(4). Advanced design, high precision and fast speed;

(5). Various alarm system to reduce waste;

(6). Photoelectric tracking system for precise bag length and position of film

(2). Film drawing down system by reliable servo motor control.

(3). Each lane dosing by servo motor driving;

(4). Advanced design, high precision and fast speed;

(5). Various alarm system to reduce waste;

(6). Photoelectric tracking system for precise bag length and position of film

| Model | WL-GH280BF-1 |

| Lane number | 1 lane |

| Packed item | Powder, small granules or liquid |

| Capacity | About 10--40 bags/min |

| Measuring method | Auger by servo motor, or other weight/volume filler |

| Measuring range | 1--10g per bag |

| Bags size | Length: 50--180 mm Width:17-30 mm |

| Film width | Max.280mm |

| Film thickness | 0.04--0.10mm |

| Sealing type | Stick bag |

| Cutting type | Zig-zag cutting |

| Film material | Laminated film,like PET/PE,OPP/PE,NY/PE,PET/AL/PE.etc. |

| Air consumption | 0.8Mpa 0.8m3/min |

| Power source | 1N+PE/50HZ/AC220V(380V)/5.2KW |

| Dimension | L1385 x W918x H2005mm |

| Weight | 350kg |

| S/N | Name | Standard |

| 1 | Touch screen | Weinview / Taiwan |

| 2 | PLC | Mitsubishi /Japan |

| 3 | Servo motor | Panasonic /Japan |

| 4 | Servo motor drive | Panasonic /Japan |

| 5 | Temp.control | Yatai./ Shanghai |

| 6 | Pneumatic elements | Airtac / Taiwan |

| 7 | SSR | Omron /Japan |

| 8 | Intermediate relay | Omron /Japan |

| 9 | Approach switch | Autonics / S.Korea |

| 10 | Color code fiber | Autonics/ S.Korea |

Options

- Weight filler

- Loading Conveyor

- Date printer

- Output Conveyor

- Weight filler

- Loading Conveyor

- Date printer

- Output Conveyor

sales@weighlin.com

sales@weighlin.com