With the rapid development of various industries, quality control increasingly stringent, rely on our core technology R&D capabilities, Welin have developed and released a variety of online dynamic automatic metal detector and combo units to meet the current and future market demand with flexible custom ability, by using latest load cell DSP technology, compact design, hi-speed, hi-precision, stable running, easy operation, various rejecting system available, integrated with upstream and downstream equipment as a full packing line for wide application, such as bags, bottle, tray, can or box package, piece medicine or seafood sorting, toy inspecting, etc; It will help to enhance the quality control, improve production capacity, reduce maintenance, reduce labor, improve production and management efficiency.

-

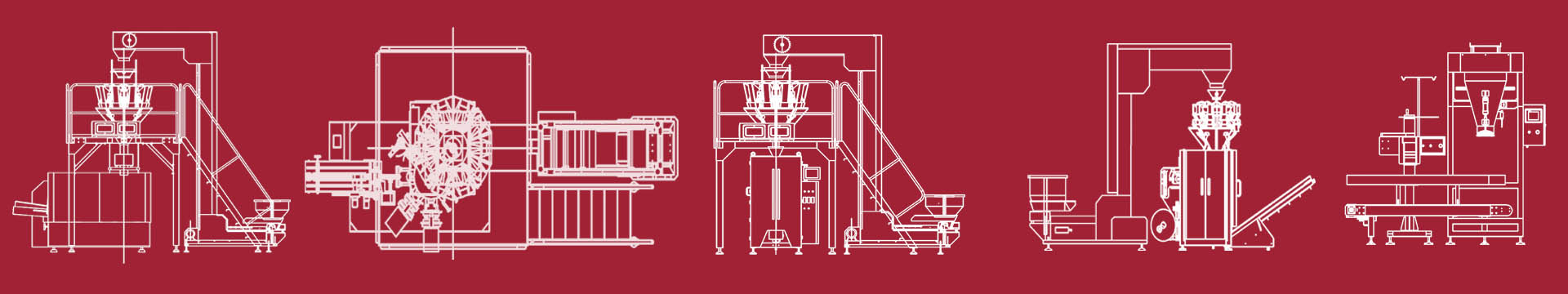

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

-

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

-

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

-

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

-

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

-

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

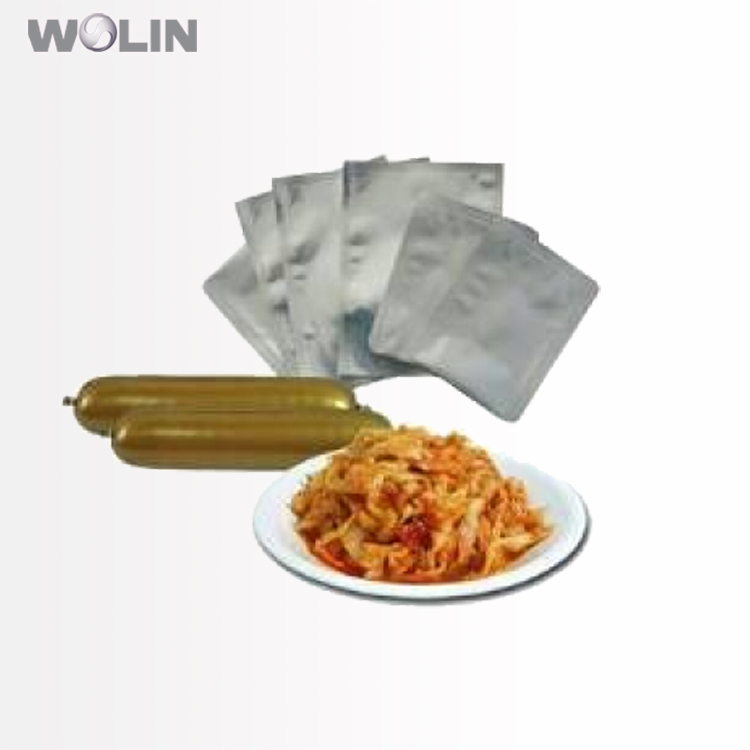

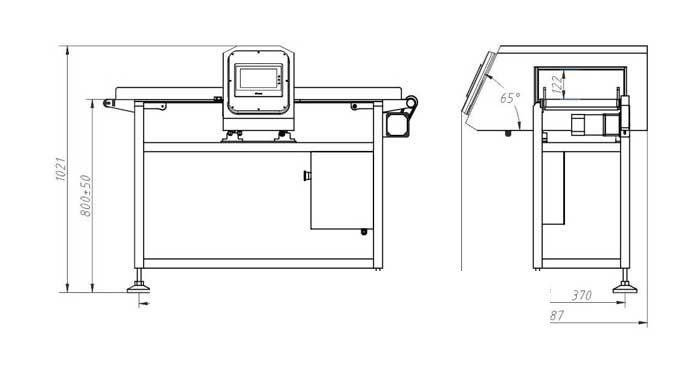

Metal Detector For Aluminum Package

This unit is special for aluminum package, it is widely used for food, chemical, textile, clothes, toys, rubber, etc It is the first choice for HACCP of food industry and GMP of pharmaceutical industry, specially suitable for flour made food, vegetable food, frozen food, sugar made food, pickles, etc

MESSAGE US

This unit is special for aluminum package, it is widely used for food, chemical, textile, clothes, toys, rubber, etc It is the first choice for HACCP of food industry and GMP of pharmaceutical industry, specially suitable for flour made food, vegetable food, frozen food, sugar made food, pickles, etc

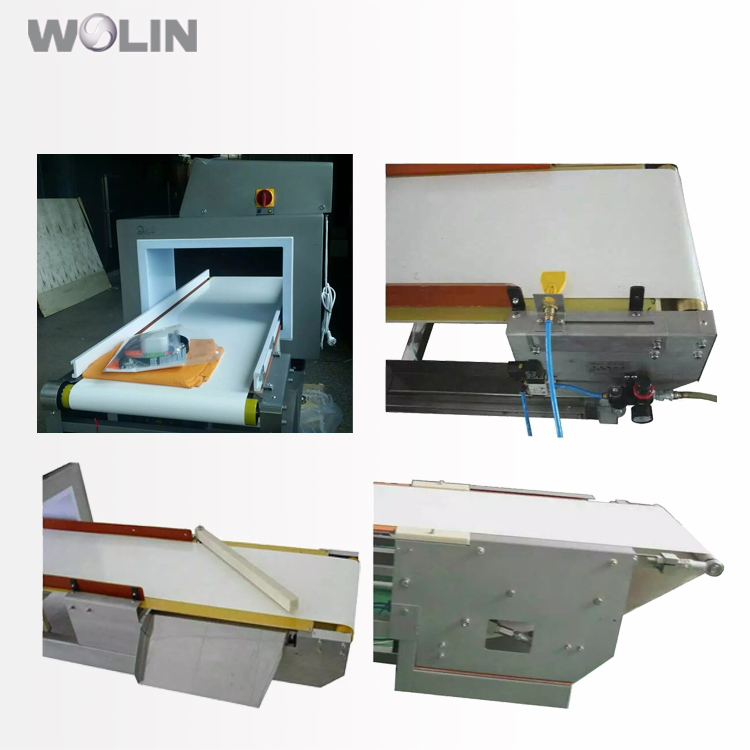

With the rapid development of various industries, quality control increasingly stringent, rely on our core technology R&D capabilities, Welin have developed and released a variety of online dynamic automatic metal detector and combo units to meet the current and future market demand with flexible custom ability, by using latest load cell DSP technology, compact design, hi-speed, hi-precision, stable running, easy operation, various rejecting system available, integrated with upstream and downstream equipment as a full packing line for wide application, such as bags, bottle, tray, can or box package, piece medicine or seafood sorting, toy inspecting, etc; It will help to enhance the quality control, improve production capacity, reduce maintenance, reduce labor, improve production and management efficiency.

With the rapid development of various industries, quality control increasingly stringent, rely on our core technology R&D capabilities, Welin have developed and released a variety of online dynamic automatic metal detector and combo units to meet the current and future market demand with flexible custom ability, by using latest load cell DSP technology, compact design, hi-speed, hi-precision, stable running, easy operation, various rejecting system available, integrated with upstream and downstream equipment as a full packing line for wide application, such as bags, bottle, tray, can or box package, piece medicine or seafood sorting, toy inspecting, etc; It will help to enhance the quality control, improve production capacity, reduce maintenance, reduce labor, improve production and management efficiency.

- Up to 32 multi-languages 7" industry control panel

- New generation coil technology avoiding blind detecting zone

- DSP display and process ensure high sensitivity and stablity

- Product self-study model for easy operation and adjust

- Preset and save 99 program reciples

- Multilevel administration enter level management

- IP56 waterproof chamber design, easy dismantle belt for clean

- Various rejector device are available as per request

| Mode | WL-MD3012 | ||||||

| Specification | I | II | III | IV | V | VI | VII |

| Accuracy FeФ(mm) |

0.8 | 1.0 | 1.2 | 1.0 | 1.2 | 1.5 | 2.0 |

| Accuracy SUSФ(mm) |

1.5 | 2.0 | 2.5 | 2.0 | 2.5 | 3.0 | 3.5 |

| Detecting height(mm) | 120 | 150 | 200 | 150 | 200 | 250 | 300 |

| Detecting Width(mm) | 400 | 500 | |||||

| Power(W) | 200 | ||||||

| Alarm | Sound light Alarm &Stop/ Reject device is optional | ||||||

| Detecting Speed(m/min) | 30-40 | ||||||

BENEFITS

Product quality control avoid the client’s complaints;

Save material cost and reduce over-weight times;

Online dynamic high speed weighing without influence the normal production;

Stable performance with low maintenance;

sales@weighlin.com

sales@weighlin.com