* For various pre-made bags such as pillow bags, gusset bags, zipper bags etc.

* For lots of application such as coffee, cookies, cereals, nuts, flower, candy etc.

-

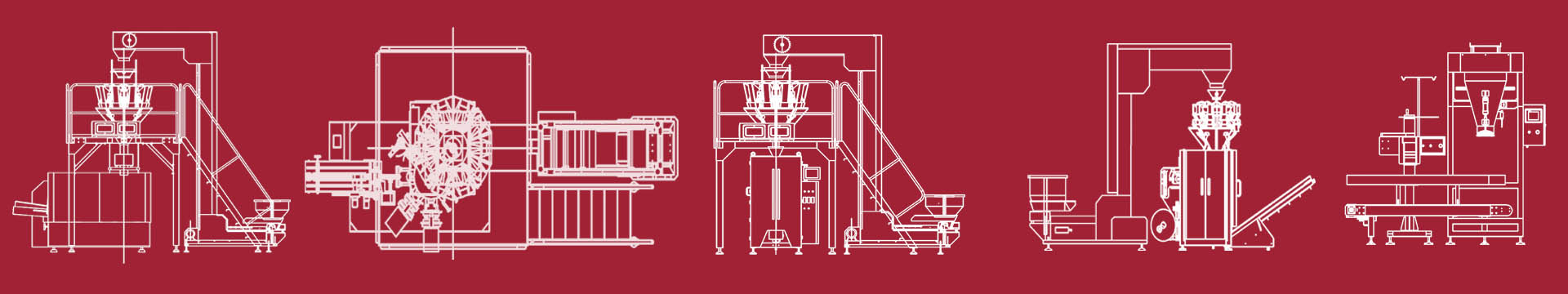

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

TURNKEY PROJECT

Auto bulk material feed, weigh, fill, seal and quality check or carton for bags, pouches, jar, boxes, can or bottle, carton, etc, widely apply for food non-food industry

-

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

AUTO MULTIHEAD FILLER

NEW Version 6-8-10-14-16-24-32 multi-head weighing filler series with the feature of hi-speed, hi-accuracy and reliable performance Adopting math numbers combination theory

-

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

ECONOMIC LANE WEIGHER

Based on years experience, Weighlin develop& produce economical and efficient linear weight filler series according to different material nature, ensure reliable performance

-

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

AUTO POUCH PACKER

Auto premade doypack ziplock pouches pick-up, open, fill, seal, batch coding, etc with other flexible options weight filler for powder, paste, liquid, powder, etc

-

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

QUALITY CHECKER UNIT

To improve products quality control, Weighlin have released a variety of online dynamic automatic weight checking sorting machine, metal detector and combo units to meet the current and future market demand with flexible custom ability,

-

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

CONVEYOR ACCESSORIES

New version design flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market

Nuts Snack Zipper Pouch Doypack Packing Machine

Full smart automatic packing line with 10 Head Multihead Weigher + 4 station doypack packing line, paired with Z elevator for zipper doy pouch packing nuts, chip, snacks

MESSAGE US

1. Bucket Elevator —— Evenly lifting bulk materials and feed to Weight Filler

2. Weight Filler —— Automatically dosing / filling materials as per preset target weight

3. Working Platform —— Used to support the Weight Filler & Daily maintenance

4. Pouch Packaging Machine —— Automatically pouch pickup - open - fill - seal - output

5. Pouch Feeding Conveyor —— Auto sending pouch to packaging machine one by one

6. Takeoff Conveyor —— Transport out the finished packs from packaging machine

7. Weight Checker —— Checking packs if over or less acceptable weights

8. Rotary Collect Table —— Collecting final finished packages

sales@weighlin.com

sales@weighlin.com